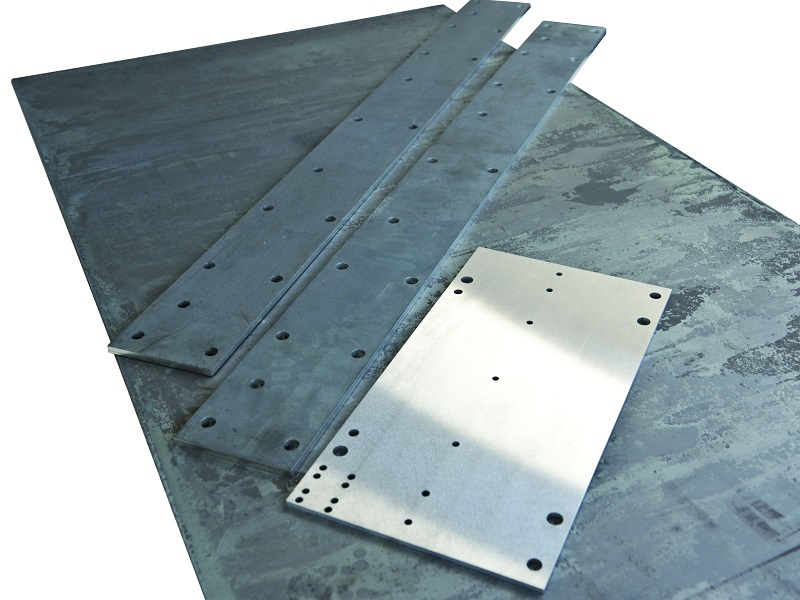

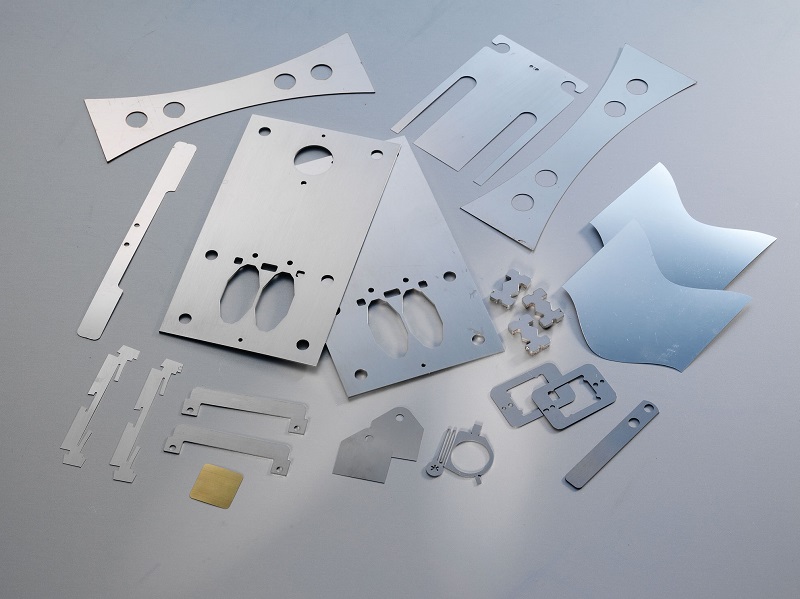

Individual laser cuts

Laser cutting

Thanks to flexible production systems, even the smallest lot sizes can be cut quickly, reliably and cost-effectively:

• With the fiber and disk laser machines, filigree parts can be manufactured in a thickness range of 0.01 to 2.0 mm with a tolerance of +/- 0.05 mm.

• From a thickness of 0.50 mm, parts can also be cut with CO2 lasers with a tolerance of +/- 0.10 mm.

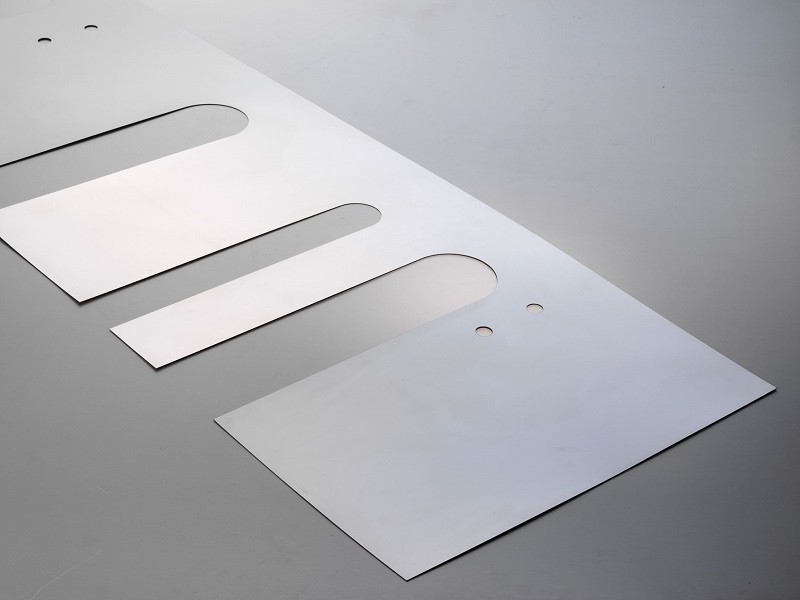

Thanks to our extensive stock of different spring band steels, we can also produce sample parts in different materials or strengths for tests. Our large stock of coil material also enables the production of long parts up to approx. 3000 mm in length.

Nickel alloys such as Alloy I (material 1.3912), Alloy K (material 1.3981) and Alloy Mu (material 2.4545) are now also available in individual strengths for laser-cut parts.

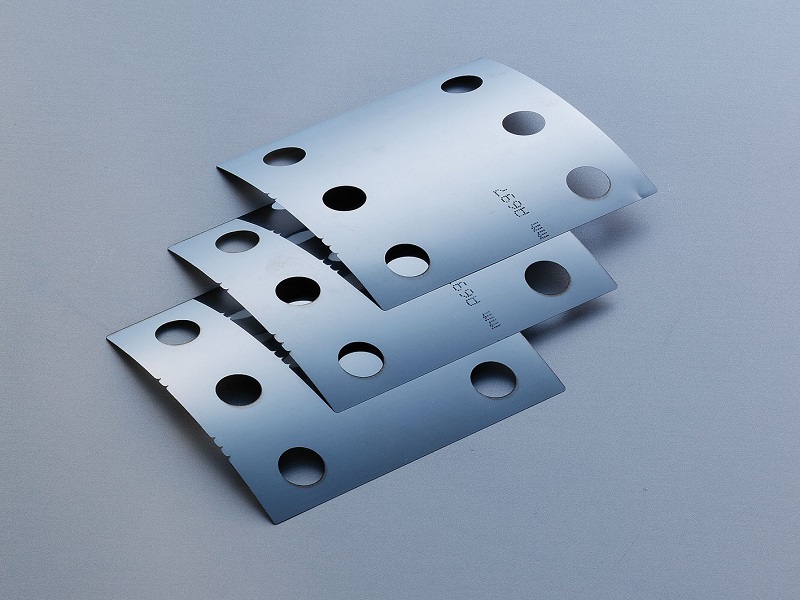

Laser marking

Laser cut parts can also be permanently marked with your part number or thickness.

Compared to embossing, engraving or etching processes, laser marking offers a high marking quality with the smallest batch sizes from 1 piece.

Flat grinding

Up to a size of 300x600 mm, drawing parts can be ground to individual thicknesses or closer tolerances of up to +/- 0.01 mm (larger formats on request).

To avoid high grinding costs, tool steel 1.2003 and stainless knife steel 1.4034 are available in many material thicknesses. The material 1.4310 cannot be machined due to its low magnetizability.

As a supplement to our band-hardened material, shims can be manufactured from piece-hardened sheets from the materials 1.2379 and 1.4034 in the thickness range from 3.0 to around 10 mm. For technical reasons, these parts must be ground to the exact thickness.

Anwendungsbeispiele